Micro SMD Component Rework Soldering Station

DH-A2 optical automatic Micro SMD Component Rework Soldering Station. If you want to repair SMD components about 1*1 mm, welcome to contact us.

Opis

Automatic Micro SMD Component Rework Soldering Station

1.Application Of Automatic Micro SMD Component Rework Soldering Station

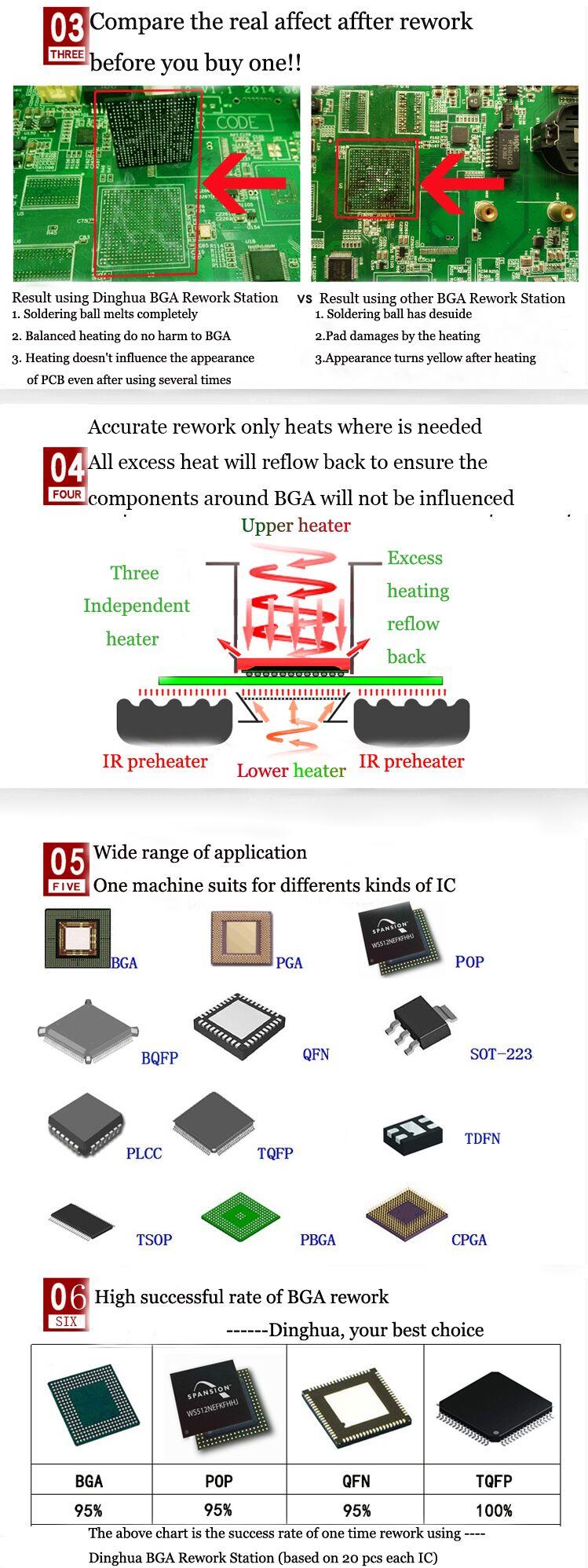

Solder, reball, desoldering different kind of chips: BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP,

PBGA,CPGA,LED chip.

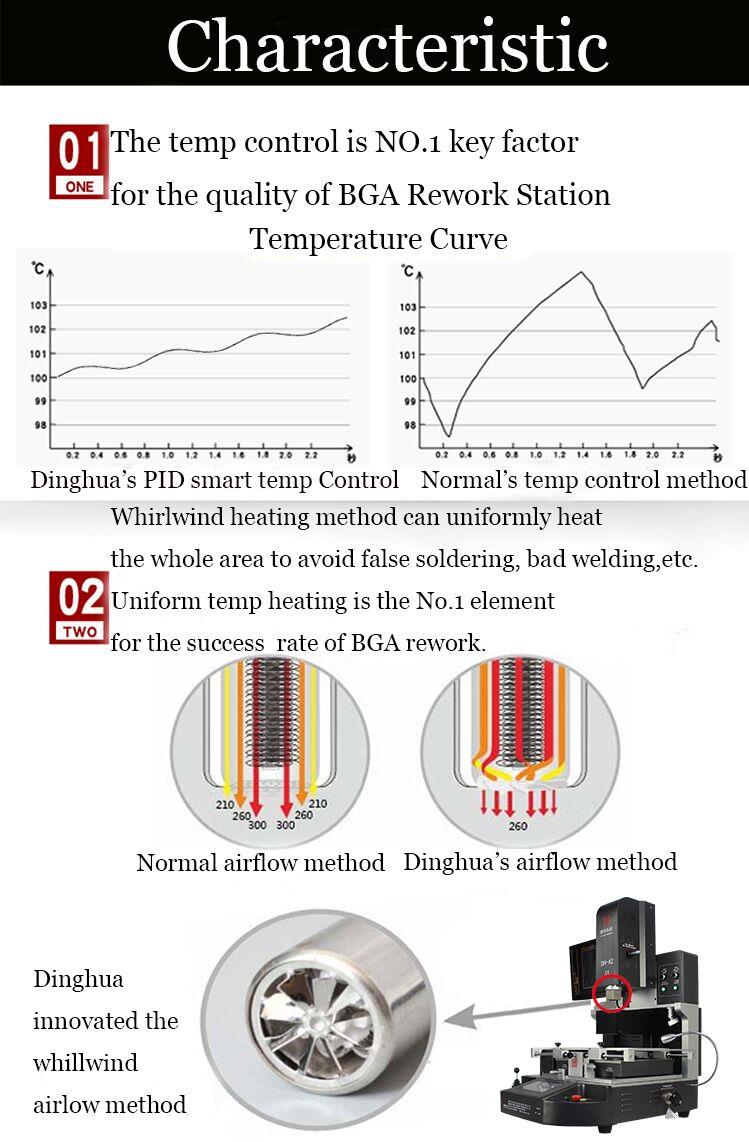

2.Product Features of Infrared Automatic Micro SMD Component Rework Soldering Station

3.Specification of laser positioning Automatic Micro SMD Component Rework Soldering Station

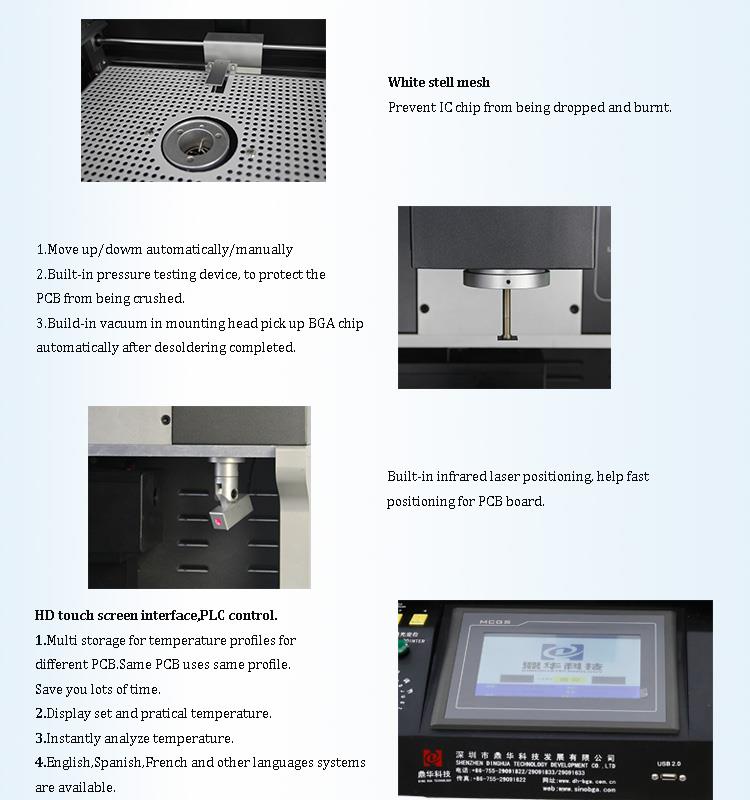

4.Details of Infrared CCD Camera Automatic Micro SMD Component Rework Soldering Station

5.Why Choose Our Hot Air Automatic Micro SMD Component Rework Soldering Station?

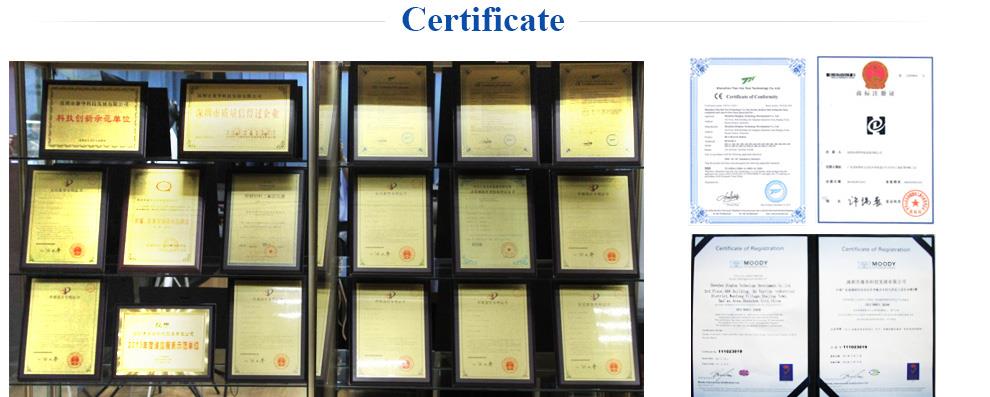

6.Certificate of Optical Alignment Automatic Micro SMD Component Rework Soldering Station

UL, E-MARK, CCC, FCC, CE ROHS certificates. Meanwhile, to improve and perfect the quality system,

Dinghua has passed ISO, GMP, FCCA, C-TPAT on-site audit certification.

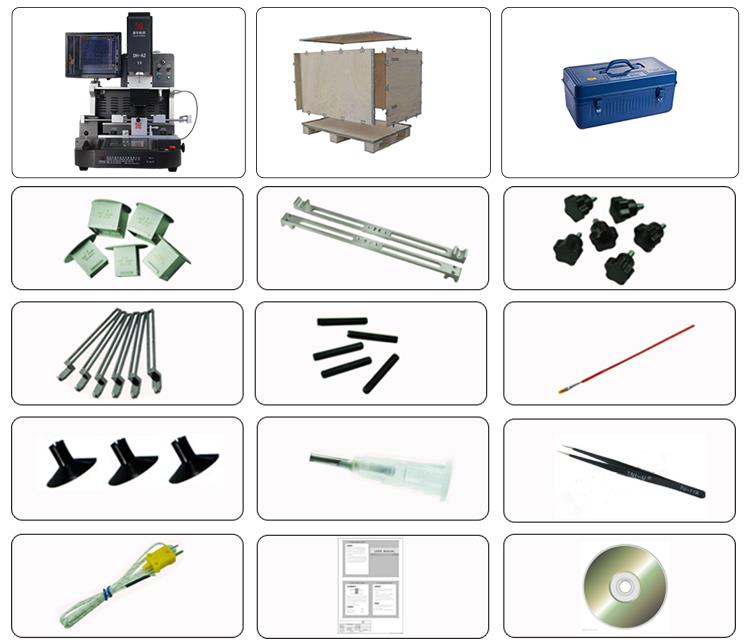

7.Packing & Shipment of CCD Camera Micro SMD Component Rework Soldering Station

8.Shipment for Split Vision Micro SMD Component Rework Soldering Station

DHL/TNT/FEDEX. If you want other shipping term, please tell us. We will support you.

9. Operation guide for Automatic Optic Align Micro SMD Component Rework Soldering Station

11. Related knowledge of Automatic Micro SMD Component Rework Soldering Station

Equipment maintenance refers to technical activities carried out to maintain, restore and enhance the state of the equipment technology.

These include maintenance that maintains a good technical state of the equipment, equipment degradation, repairs that resume its function

after a failure, and technical activities that enhance the state of the equipment Micro SMD Component Rework Soldering Station.

The basic contents of equipment maintenance include: equipment maintenance, equipment inspection and equipment repair (including fault

repair and active repair).

Interpretation

Technical activities performed to restore its functionality after the state of the equipment has deteriorated or failed, including various planned

repairs and unplanned fault repairs and accident repairs. Also known as equipment repair.

Job indicator

The results of equipment maintenance should be calculated by the corresponding technical and economic indicators, and there are two types of

indicators that reflect the effect of equipment maintenance work:

1. Post-maintenance technical status indicators.

2. Maintenance activity economic performance indicator

· The task of equipment maintenance work is: according to the law of the equipment, often maintain the equipment maintenance, extend the normal

use stage of the parts; carry out the necessary inspection of the equipment, and timely grasp the equipment situation, in order to take appropriate

measures before the parts enter the equipment problem Make repairs.

· Frequently occurring equipment Micro SMD Component Rework Soldering Station problems include: wear, corrosion, leakage, impact, erosion, scaling,

deformation, etc., due to the variety of equipment in various industries, the form of expression is also diverse.

·The traditional maintenance methods mainly include: lubrication, repair welding, machining, scrap update, error adjustment, and sulphur cleaning.

· Western advanced maintenance and repair methods: polymer composite technology, nano material technology, ceramic material technology, rare metal

materials technology, etc., such as: Fu Shilan polymer composite technology can quickly and efficiently achieve online maintenance, independent maintenance;

Some nano-ceramic technologies can make the equipment more practical and durable on the basis of maintaining high strength and high hardness, lighter and

more resistant to corrosion.

With the development of technical specialization, AME equipment maintenance work should be separated from the enterprise. That is, a professional maintenance

factory or a regional maintenance center is established according to different aspects such as production use, equipment type, and regional division. Professional

repair factories provide paid services to enterprises through economic contracts, and gradually form a socialized maintenance system. These maintenance specialization

organizations will carry out basic data accumulation for the performance indicators of advanced manufacturing equipment, establish equipment fault libraries and model

libraries, and make maintenance decisions through computer aided equipment Micro SMD Component Rework Soldering Station. This will enable the rational allocation

of resources, which will help the production enterprises to focus on the main business, to concentrate on the main body, to reduce the burden on the enterprise, to improve

efficiency and enhance vitality, and to further promote the further division of labor and social productivity. The state can adopt laws and regulations to cultivate and standardize

the equipment maintenance market, standardize the qualification certification, maintenance quality and price of the equipment maintenance enterprises entering the market,

and mediation of maintenance transaction disputes, and change the “big and complete” for the enterprise. The “small but complete” equipment Micro SMD Component Rework

Soldering Station maintenance system creates a good external environment. The author foresees the rise of professional maintenance companies and will flourish like third-party

logistics.

Related products:

Motherboard repairing machine

SMD micro components solution

SMT rework soldering machine

IC replacement machine

BGA chip reballing machine

BGA reball

IC chip removal machine

BGA rework machine

Hot air solder machine

SMD rework station